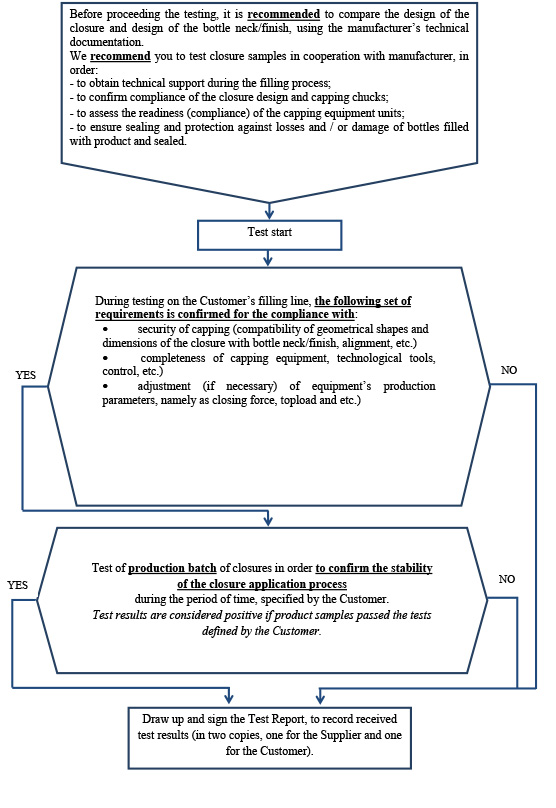

Testing of the closure samples is recommended to be carried out in cooperation with the manufacturer, in order to:we recommend to our Customers to conduct testing on the Customer’s filling lines, as well as conduct laboratory tests to confirm the compliance with

-closure design and design of the capping chucks, using the manufacturer’s technical documentation.

-closure design and design of the bottle neck/finish;

Testing of the closure samples the following set of requirements is confirmed for the compliance with:

-obtain technical support directly during the filling process;

-confirm compliance of the closure design and capping chucks;

-assess the readiness (compliance) of the capping equipment units;

- ensure sealing and protection against losses and / or damage of bottles filled with product and sealed

During testing on the Customer’s filling line, the following set of requirements is confirmed for the compliance with:

- security of capping (compatibility of geometrical shapes and dimensions of the closure with bottle neck/finish, alignment, etc.)

- completeness of capping equipment, technological tools, control, etc.)

- adjustment (if necessary) of equipment’s production parameters, namely as closing force, topload and etc.)

After testing of closure samples, we recommend to test production batch of closures in order to confirm the stability of the closure application process during the time specified by the Customer.

Laboratory tests for compliance with the established requirements are recommended to be carried out according to the manufacturer's technical documentation.

Methods (tests, measurements, analysis) should be as close as possible to the conditions of product application.

Test results are considered positive if product samples passed the tests that were determined by the Customer.

Based on the test results and acceptance tests it is recommended to draw up and sign a Test Report, in order to record received test results with submission of a copy of Test Report to the closure manufacturer.

Depending on the conditions of work, the form of Test Report can be reviewed (by the Manufacturer or Customer), while providing the opportunity of record of objective assessment of the results of work performed and decisions made.

In the Test Report of closure samples indicates:

- compliance of tested samples of closure with specified requirements;

- conclusion on the technological readiness of the Customer production to use of manufacturer’s closures;

- recommendations for application of closure;

- Customer’s readiness to use the manufacturer’s closure on an industrial scale.